Power Regeneration Unit

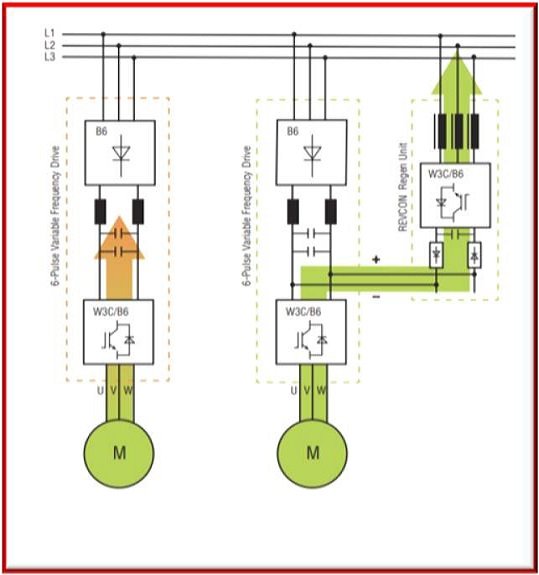

The universal REVCON regen unit RLD enables the use of the braking energy caused by any standard variable frequency drive- VFD. Compared to the brake chopper,the REVCON RLD is using regenerative braking instead of converting the energy into heat.The energy is fed into the mains supply through a unique inverting procedure and creates only a small DC bus voltage raise.

Power Regeneration Unit

The patented switching principle of the REVCON regen units is unique and guarantees an extremely high product lifetime and very low losses.Due tothe high efficiency the design of unit is extremely compact.Due to its unique control,no programming or parameter setting is required.plug & play! All our regen units are available for all low voltage 3-phase supplies and covers power from 2kW up to 250kW,with an open end in parallel setup!

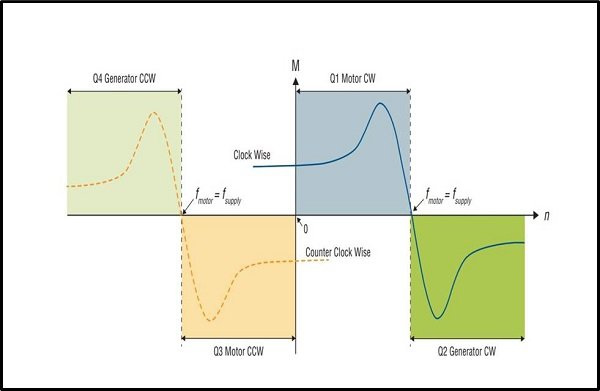

Any standard asynchronous motor can be re-generative. The picture above show the four possible quadrants Of operation of a motor direct on line.

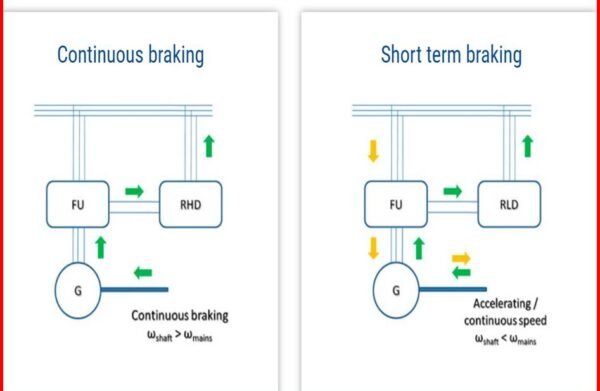

The application could be a continuous braking type e.g Engine Testing Setups , Escalators or Short term Braking type like Cranes , Elevators, centrifuge etc.

Advantages – RLD Units

- small compact size including regen choke

- braking energy of drive systems is regenerated into the network

- regen power can be sized to the application (e.g. 90kW drive with 30kW regen unit)

- capacity range 4kW to 433kW

- high flexibility: mains voltages range from 230, 400, 460, 500 to 690V

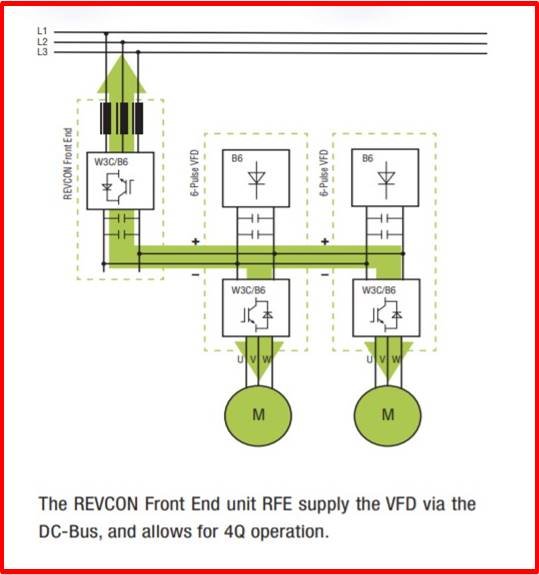

- DC coupling of several drives possible.

- low-loss and high-quality IGBT modules

- high reliability: electronic overload protection for feedback operation

- monitoring of mains voltage, phase rotation and temperature

- high efficiency of > 98% due to effective real time control and analogous

- function principle

- enables highly dynamic braking operations

- user-friendly start-up, as no programming or settings are required

- Significant reduction of heat loss by regenerative operation.

- due to the innovative concept, the power feedback unit is maintenance-free

- duty cycle 50%

Active principle energy recovery module REVCON® RLD

- The energy is generated from the mechanical side of the asynchronous motor, when a torque is applied to the shaft.

- The energy is fed to the DC bus via the frequency converter.

- The voltage in the DC link of the inverter and the regenerative unit increases.

- The energy is fed back to the mains through the energy recovery module.